This is in contrast to thicker hot rolled sections that are shaped while the steel is molten hot.

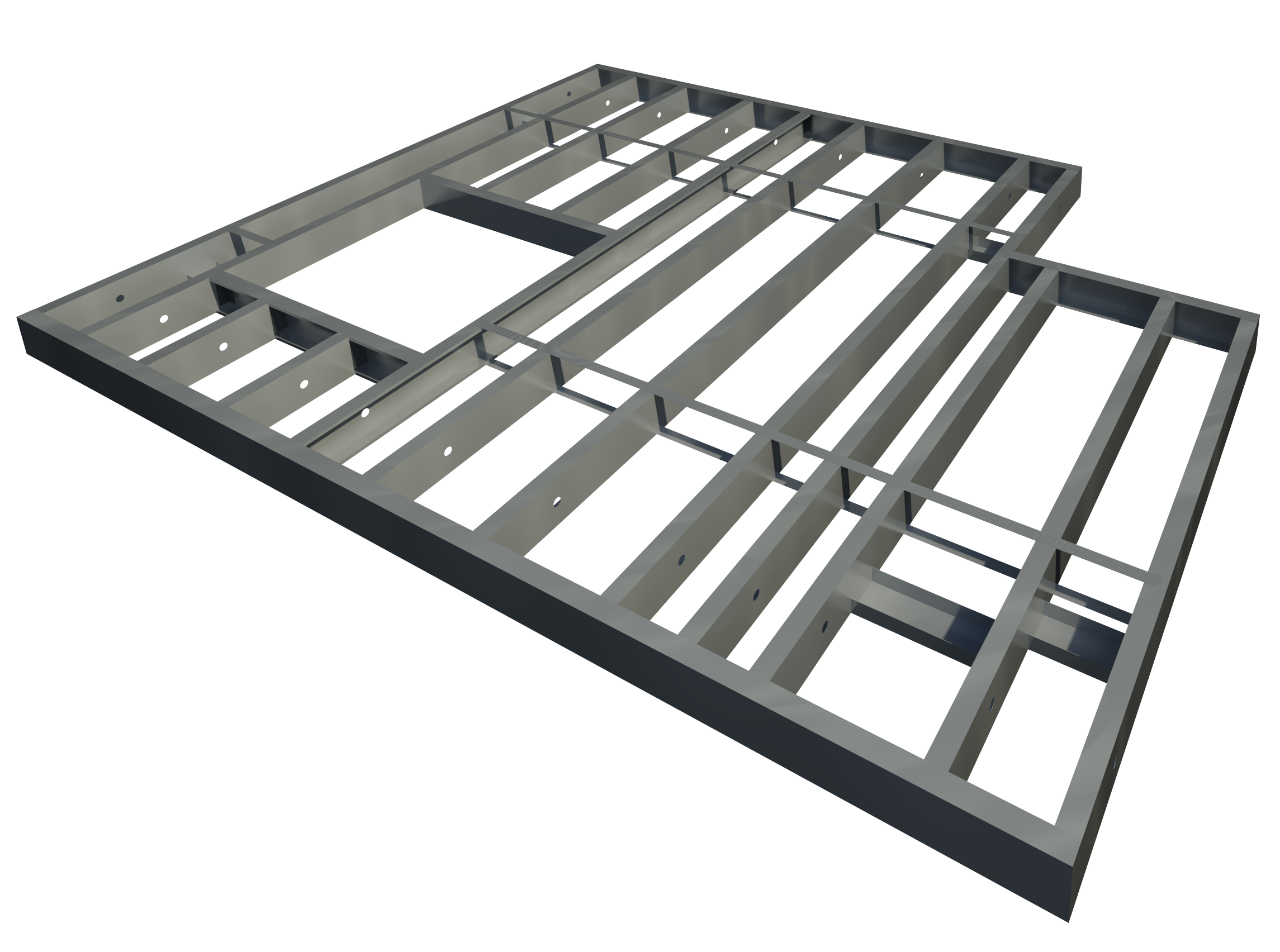

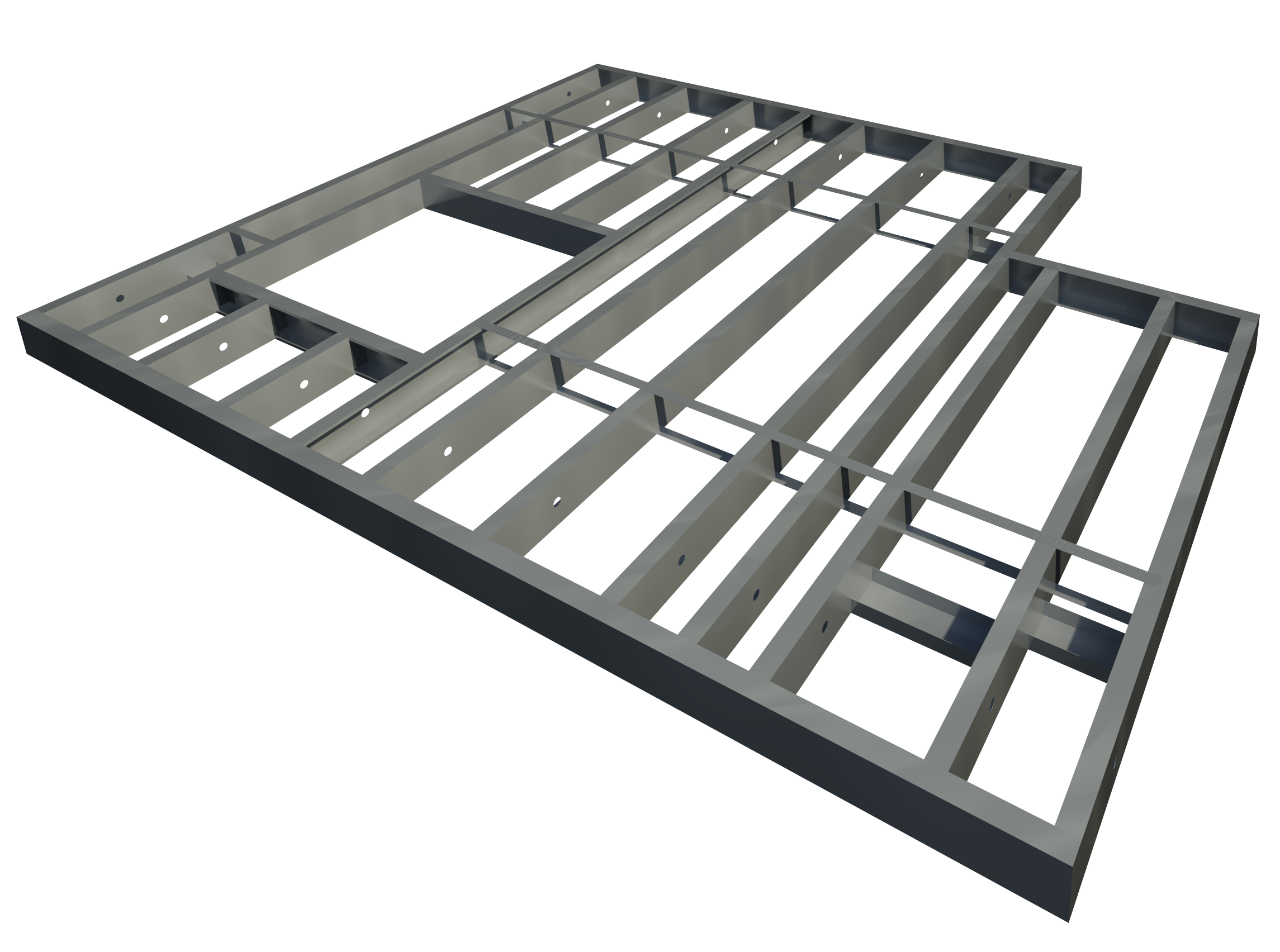

Light gauge steel floor framing.

We see what the future for walls holds and we are acting on it with steel framing products that perform as a system backed by intelligent design tools and fully capable engineering services.

Advantages of light gauge steel framing the name of the game with lgs is precision.

Also since it goes to recycling facilities the waste can even produce some income to offset project costs.

Light gauge steel framing is easily assembled with c joist components which are economical lightweight and come conveniently pre cut.

Every joist is cold rolled a galvanized steel sheet is pulled through a die that gives the joist its shape perfectly straight and to the exact dimension you specify see sidebar above.

Light gauge framing systems all steel mid rise wall and floor system packages are constructed of the highest quality products and services guaranteed to meet the needs of any mid rise project.

All steel offers panelized load bearing walls and 3 different types of floor systems to suit the needs and expectations of the individual project and.

Light gauge steel construction is very similar to wood framed construction in principle the wooden framing members are replaced with thin steel sections.

No longer just studs tracks and headers.

Cold formed steel structures are both lightweight and strong helping the job to get completed quickly.

Unlike wood steel framing is non combustible and also resists warping rotting and insect damage.

Steel framing produces far less on site waste than wood framing making debris removal less costly.